Marine Wastewater Treatment

What is Marine Wastewater Treatment?

Marine wastewater treatment or Marine sewage treatment is the process of converting wastewater into an effluent that can be reused or returned to the water cycle with minimal environmental impact in compliance with the regulatory requirements. FMD are specialists in marine wastewater treatment and marine sewage treatment.

The FMD Sequencing Batch Reactor (SBR)

An evolution in marine wastewater treatment that is so simple… it almost seems impossible.

The SBR series of advanced marine wastewater treatment plants are purpose-designed to treat the combined marine wastewater sources of Grey, Black, Galley, Laundry and dewatered food waste liquor as a single influent – simplifying management and maximising treatment to a level beyond IMO MEPC 227(64) regulatory requirements, with nutrient removal available to exceed IMO MEPC 227(64) 4.2.

Cost Effective & Reliable

We provide a cost effective and reliable marine wastewater treatment solution. The SBR systems have one of the lowest treatment costs per cubic meter available on the market today and when combined with our industry leading warranties an SBR can deliver the lowest life cycle costs available.

These plus many other benefits of SBR ownership make it an ideal solution for Naval, Offshore, Cruise, River Cruise, Superyachts and Commercial applications.

The SBR is a biological marine wastewater treatment system that is so effective in its simplicity, we have eliminated the need for membranes, aeration blowers and wastewater treatment chemicals while still exceeding the latest IMO requirements. Industry leading marine wastewater treatment and marine sewage treatment.

SBR Advantages

- NO marine sewage treatment chemicals

- NO aeration blowers

- NO membranes

- NO foaming

- Low power consumption

- Low maintenance requirements

- Extreme resistance to toxic shock from laundry or cleaning chemicals

- High load, low load or NO load NO problem

- Can digest fat/oil/grease (FOG)

- Fully automated with limited operator requirement

- Long life equipment with very Low Life Cycle Cost

How it’s done

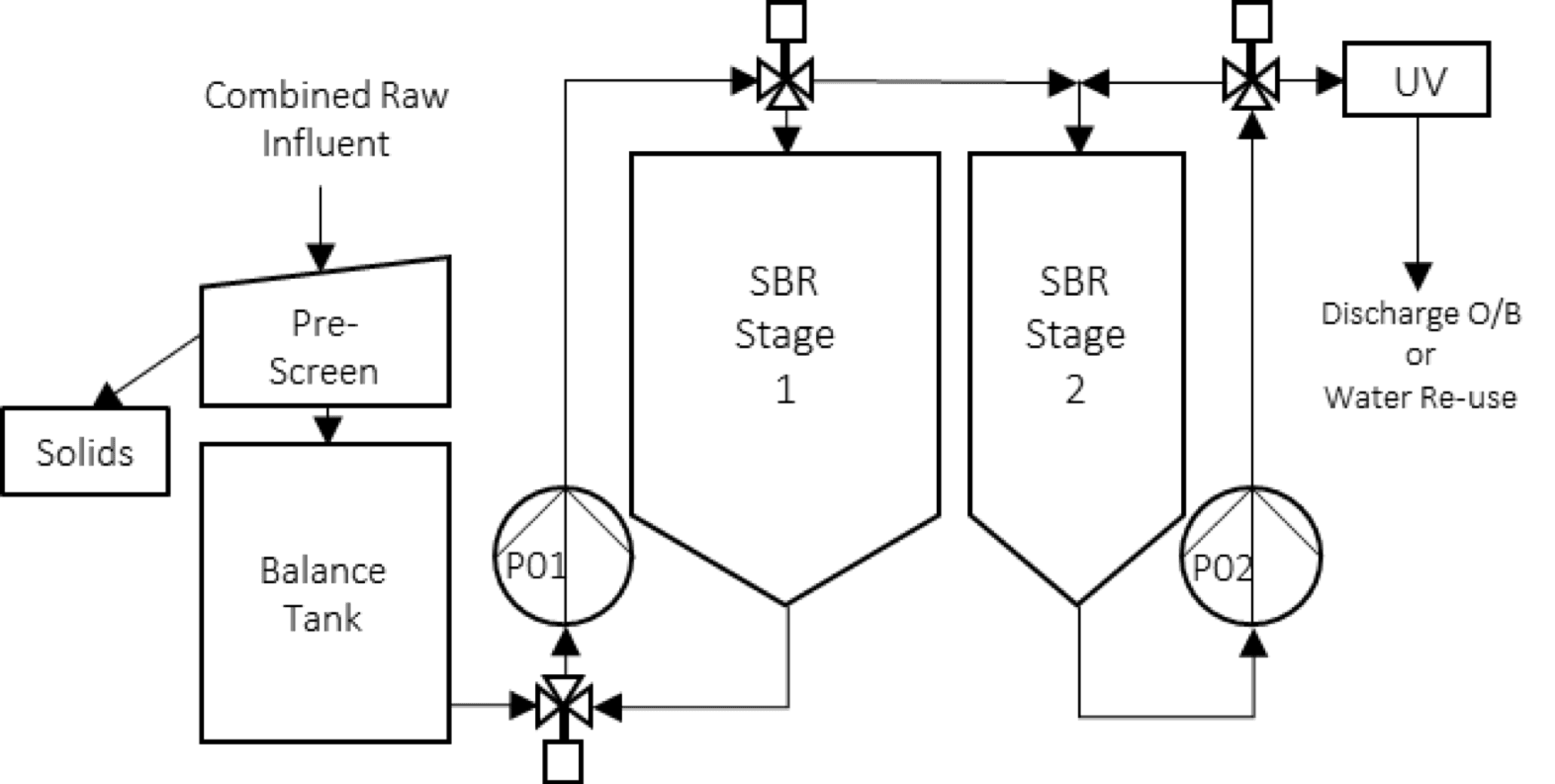

This simplified diagram of the FMD SBR shows wastewater being drawn from the balance tank being recirculated over Stage 1 by pump for a set time then transferred to Stage 2 to be recirculated by pump for a set time before discharge via UV.

The SBR is fundamentally different to systems currently in use, due to the nature of the biofilm in the system it has. This arrangement is fundamentally different to other marine wastewater treatment philosophies within the marine industry – where typically oxygen is forced into the nutrient rich wastewater to keep the biomass aerobic.

The FMD SBR plants are fully scalable from less than 1m3/day to beyond 5000 m3/day:

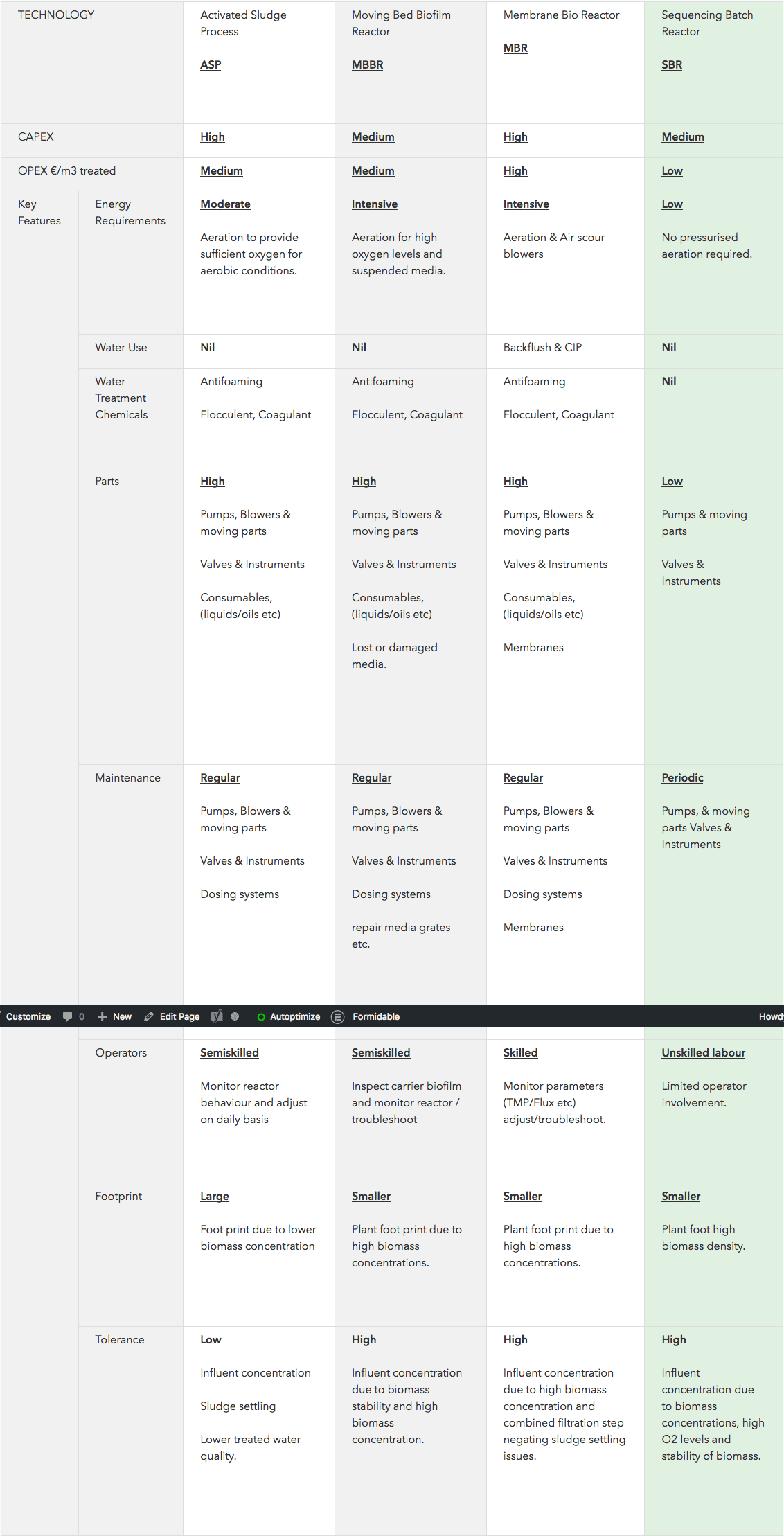

| TECHNOLOGY |

Activated Sludge Process ASP |

Moving Bed Biofilm Reactor MBBR |

Membrane Bio Reactor MBR |

Sequencing Batch Reactor SBR |

|

| CAPEX | High | Medium | High | Medium | |

| OPEX €/m3 treated | Medium | Medium | High | Low | |

| Key Features | Energy Requirements |

Moderate Aeration to provide sufficient oxygen for aerobic conditions. |

Intensive Aeration for high oxygen levels and suspended media. |

Intensive Aeration & Air scour blowers |

Low No pressurised aeration required. |

| Water Use | Nil | Nil | Backflush & CIP | Nil | |

| Water Treatment Chemicals |

Antifoaming Flocculent, Coagulant |

Antifoaming Flocculent, Coagulant |

Antifoaming Flocculent, Coagulant |

Nil | |

| Parts |

High Pumps, Blowers & moving parts Valves & Instruments Consumables, (liquids/oils etc) |

High Pumps, Blowers & moving parts Valves & Instruments Consumables, (liquids/oils etc) Lost or damaged media. |

High Pumps, Blowers & moving parts Valves & Instruments Consumables, (liquids/oils etc) Membranes |

Low Pumps & moving parts Valves & Instruments |

|

| Maintenance |

Regular Pumps, Blowers & moving parts Valves & Instruments Dosing systems |

Regular Pumps, Blowers & moving parts Valves & Instruments Dosing systems repair media grates etc. |

Regular Pumps, Blowers & moving parts Valves & Instruments Dosing systems Membranes |

Periodic Pumps, & moving parts Valves & Instruments |

|

| Operators |

Semiskilled Monitor reactor behaviour and adjust on daily basis |

Semiskilled Inspect carrier biofilm and monitor reactor / troubleshoot |

Skilled Monitor parameters (TMP/Flux etc) adjust/troubleshoot. |

Unskilled labour Limited operator involvement. |

|

| Footprint |

Large Foot print due to lower biomass concentration |

Smaller Plant foot print due to high biomass concentrations. |

Smaller Plant foot print due to high biomass concentrations. |

Smaller Plant foot high biomass density. |

|

| Tolerance |

Low Influent concentration Sludge settling Lower treated water quality. |

High Influent concentration due to biomass stability and high biomass concentration. |

High Influent concentration due to high biomass concentration and combined filtration step negating sludge settling issues. |

High Influent concentration due to biomass concentrations, high O2 levels and stability of biomass. |

|