Permanent Washable Air Filters

General Principles of Air Filters

The common assumption is that air filters work on the sieve or strainer principle, whereby particles in the air are trapped if they are larger than the filter material “hole” size , and can pass through if they are smaller.

Your typical Air filter does not work in this way however.

The filtration material typically consists of a random web of fine fibres that are very deep in comparison to the particle size. The web of fibres must be dense enough to force the particles along a zig-zag course inside the filter material.

Particles that hit the web of fibres and are caught and retained by one or more of the following mechanisms:

1. The fibres may be adhesive-coated (NOT the FMD type )

2. The web fibres may have an electrostatic charge (the FMD type) which attracts the dust particles.

3. Very small particles are held by a physical attraction (intermolecular bonding) known as Van Der Waal’s Force (the FMD type)

Permanent Washable Panel Filters

There are only a few synthetic fibre-forming polymers that have the property of being electrostatically charged by the friction of the air stream passing over them and it accounts for the high efficiency filtration with relatively low pressure drop found in the FMD type filters:

- Typical initial ΔP 90 Pa

- Recommended final ΔP 300 Pa

- Maximum final ΔP 450 Pa

The FMD permanent air filters are an efficient, cost-effective and environmentally responsible solution to some of the inherent problems with disposable air filters. They are easily retro-fitted into AHUs, fan-coil units, machinery space air intakes or even engine turbocharger filters.

Already extensively installed on Superyachts, cruise ships, offshore platforms and Naval vessels the filters have been independently tested to ASHRAE 52.2 and are certified to MERV 9 / EU M5.

Enquire

|

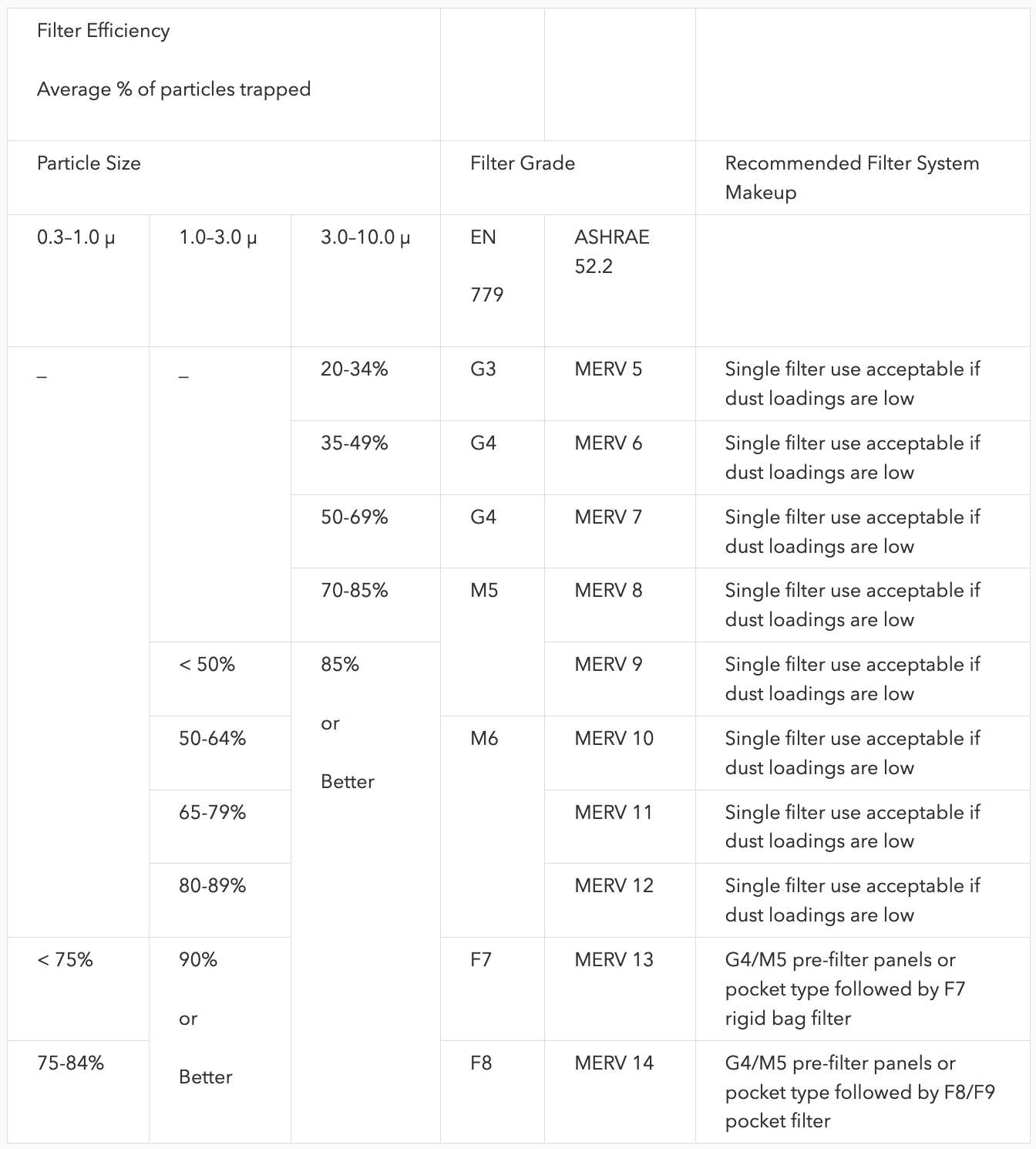

Filter Efficiency Average % of particles trapped |

|||||

| Particle Size | Filter Grade | Recommended Filter System Makeup | |||

| 0.3–1.0 µ | 1.0–3.0 µ | 3.0–10.0 µ |

EN 779 |

ASHRAE 52.2 | |

| _ | _ | 20-34% | G3 | MERV 5 | Single filter use acceptable if dust loadings are low |

| 35-49% | G4 | MERV 6 | Single filter use acceptable if dust loadings are low | ||

| 50-69% | G4 | MERV 7 | Single filter use acceptable if dust loadings are low | ||

| 70-85% | M5 | MERV 8 | Single filter use acceptable if dust loadings are low | ||

| < 50% |

85% or Better |

MERV 9 | Single filter use acceptable if dust loadings are low | ||

| 50-64% | M6 | MERV 10 | Single filter use acceptable if dust loadings are low | ||

| 65-79% | MERV 11 | Single filter use acceptable if dust loadings are low | |||

| 80-89% | MERV 12 | Single filter use acceptable if dust loadings are low | |||

| < 75% |

90% or Better |

F7 | MERV 13 | G4/M5 pre-filter panels or pocket type followed by F7 rigid bag filter | |

| 75-84% | F8 | MERV 14 | G4/M5 pre-filter panels or pocket type followed by F8/F9 pocket filter | ||

AHU, Fancoils

& Machinery Air Intakes

Washable Permanent Panel Filters

12 Year Warranty

Say NO to the Cost of Disposable Filters

- 316L Stainless Steel Frame or Frameless Ultrasonically Welded

- Reduce Storage Requirements for Spare Filters

- Reduce Coil Blockages from Failed Filters

- Reduce Your Environmental Impact

- Carbon footprint – only once for manufacture and transport

- No Disposable Filters to Landfill.

- Eliminate Cutting & Fitting Time on Pre-Filters

- Eliminate Buy, Ship & Disposal Costs

Dirty filters are simply washed and dried, ready for re-use.

Engine turbocharger air intake filters

Washable Permanent Turbo Filters

10 year warranty.

These filters are custom made for the turbochargers from manufacturers such as ABB, MAN and Mitsubishi.

- Simply Wash with a Degreaser and Dry

- Eliminate Cutting & Fitting Time

- Eliminate lost Life Cycle Costs of Purchasing, Shipping & Disposal